When using the test machine to measure very small distances, the extension readings can be incorrect due to the stiffness of the machine, load cell bending and grip pin movement.

To overcome this there is a setting for machine stiffness that can be set and the extension readings will be compensated for in the embedded software

The newly compensated extension readings are available as a scheme setting in both standalone mode (machine only) or with test software (NEXYGEN MT or

NEXYGENPlus). There is space for 10 individual compensation settings.

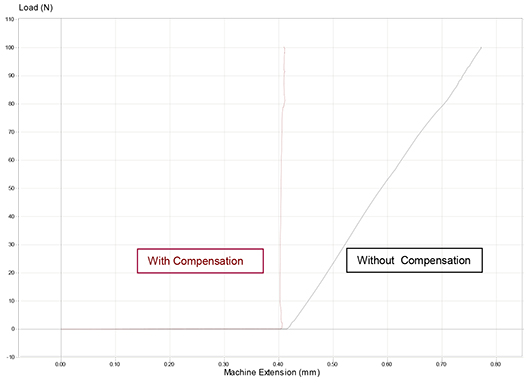

The following graph shows one test with compensation and one without. It can clearly be seen that compensation makes a considerable difference to the extension readings. This test was performed with a 100N load cell in compression.

How to set the machine stiffness on your materials testing machine

How to set the machine stiffness on your materials testing machine

For

Tension a solid metal bar must be gripped between eye ends. For

Compression, machine eye ends or compression platens can be pressed together.

With the correct load cell fitted, switch on the test machine and allow it to initialize.

From

The top level Test / Edit screen on the test machine console:

Select

Edit

Select

Global

Press the > key twice

Select

Set Machine Stiffness

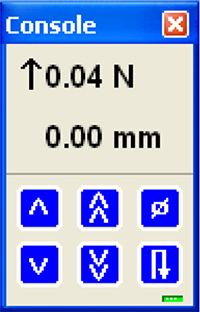

If no schemes are currently set the display will show

Empty 1….10.

A previous scheme can be edited to use again.

Select the desired scheme to be configured using the < > keys

The scheme can be given a name usually associated with the load cell type for example T100N or C100N for tension or compression.

Select

Setup

Select the test mode either

Tension or

Compression

Select

Set Preload Value

Select

Preload and enter the force to start the extension readings. This is recommended to be 0.5% of the load cell value. Example 1000N load cell, preload = 5N. Other units can be used such as gf or lbf.

Select

Speed and enter

1mm/min. (it is highly recommended that no higher speeds are used).

When preload and speed have been set press the

Enter key once.

Select

Set Limit Value

Select

Limit and set this to the target load needed. This can be full range of load cell or a percentage of (if the test does use full load).

Select

Speed and enter

1mm/min.

When limit and speed have been set press the

Enter key.

The settings are now complete.

Select

Perform. The display will show ‘Performing Test Machine Stiffness’

The test machine will do two cycles. The first cycle checks the physical deflection in the machine and load train. The second cycle performs the measurement compensation for the movement found.

When fully complete the display will return to the

Select Scheme name screen.

To return to the console top-level menu press the

Enter key three times.

Using the scheme in a test (stand alone test machine only)

The stiffness compensation scheme that has been set will be stored in the test machine console memory and can be selected in any test set up.

From the top menu select the test to edit using the < > keys

Select

Edit and then

Setup

Select

Test Type

Press the > key once

Select

Machine Stiffness

Use the left hand up arrow key ^ on the console to select

Enable or

Disable scheme

Use the < > keys to select the scheme name and setup to be used

Press the

Enter key to exit

Select all other test parameters as normal

When a test is now run this scheme (if enabled) will be used and extension readings and results will be compensated.

Note: As the machine memory holds the Stiffness scheme, to clear it from a test setup, it can be disabled in the settings as mentioned above or a Ram Dump of the machine can be performed.

Using the scheme in a test with software (NEXYGEN MT or NEXYGENPlus)

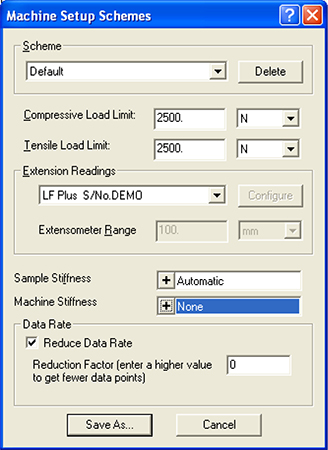

With the test machine switched on and PC connected, open the correct console (

EZ and Plus Series)

Right Click on the console and select

Machine Setup Schemes

Select + button next to Machine Stiffness and from the drop-down menu select the scheme name required.

Select

Save As... to save the console and use this Machine Stiffness setting.

When you open a batch file and run a test, the software using the saved console’s extension readings and results will be compensated.