Blister packs are pre-formed plastic

packaging used in the

medical and

pharmaceutical industries for packing pills, capsules, syringes, tablets and small medical instruments.

A blister pack is a laminated blister card with thermo-formed or cold formed cavities with paperboard, aluminum or plastic protective lid. It is important that the blister packs are manufactured to specifications and withstand contamination, moisture, tampering and unwanted separation.

These products need to arrive safe into the hands of the end-consumers without degradation. A 180 degree peel test on blister packs using a

motorized force tester, such as the

CS1100, with the proper

grips will accomplish this task and provide results to verify the integrity of the blister pack.

In this application note you will learn how to test syringe blister packs in accordance to ASTM F88 and JIS Z0238 standards.

What is Required

CS1100 Motorized Force Tester

The

CS1100 force tester is well adapted in production environments to do

peel testing. With a small foot print the

CS1100 force tester can easily be set on a table for inline production testing. The CS1100 tablet touch screen makes the task even easier for the user with only one touch of the finger to begin the peel test. The force tester has been designed with quietness in mind which makes it the perfect solution in the lab environment where silence is at a premium.

Self-Tightening Wedge Grips

Self-Tightening Wedge Grips

The

self-tightening wedge grip model 01/4647 and serrated grip face model 01/4648 are the grips of choice for this application. Handling small tabs is often difficult but by using the

self-tightening wedge grip the tabs of the blister pack will always be centered.

The selection of proper grips is critical for successful testing. For example, if serrated grip faces are too narrow for your specimen and the specimen rips in the grips, the tests results will be incorrect due to premature failure induced by the grip faces, therefore yielding inconclusive results.

If the grip face width is correct but the surface of the grip face is too smooth for the specimen, you will have slippage and therefore also incorrect results.

The grip faces on the

self-tightening wedge grips used for the syringe peel test in this example have the proper grip face width with a serration that will not allow the blister pack tabs to rip or slip.

Make sure to

contact your Ametek Sales Representative if you have any questions selecting the proper

grips for your application.

The 180 Degree Peel Test

Place the syringe blister pack in the grips with the tabs 180 degrees apart.

TIP!

A Qtip may be used as an aide to guide the lower tab into the grip when working in such tight areas. The Qtip is safer to use than your fingers.

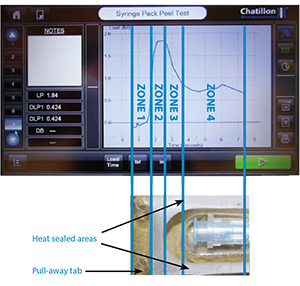

The object of this blister pack peel test is to separate the syringe lidding from the blister cards and measure peak force. See illustration of what to be expected during the blister pack peel test;

Zone 1

Zone 1

Start of test, beginning to pull on the tabs until the force starts to increase as the tabs become fully taught.

Zone 2

Pulling both tabs apart in maximum adhesion area and reaching peak force.

Zone 3

Reached tapered/reduced adhesion area on blister pack and force drops.

Zone 4

Pulling on tapered adhesion area until end of test at 1.5” of travel.

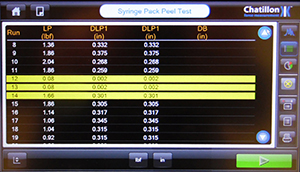

Results from CS1100 Tests Screens

Data points load / displacement

Highlighted data points show data exclusions

Statistical data screen

Download this application note as PDF