There are several important factors to consider when designing medical packaging. Not only does the packaging have to be easy to open for frail hands and hands wearing gloves, it also has to prevent the medical device inside the packaging from breaking or being damaged during the opening.

In this application note we will go through the test equipment needed to perform 180° T-peel tests, 180° peel tests and 90° peel tests on

medical packaging.

What is Required

CS2-225 Digital Force Tester

The

CS2-225 force tester is well adapted in production environments to perform peel testing.

With a small foot print the

CS2-225 force tester can easily be set on a table for inline production testing. With the tablet touch screen, it only takes one touch of the finger to start the peel test.

The force tester has been designed with quietness in mind which makes it the perfect solution in the lab environment where silence is at a premium.

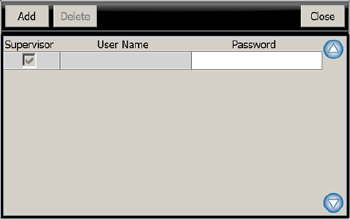

The

CS2-225 force tester features multiple login and permission access levels enabling the Manager access as an administrator with rights to define the setup while additional users can have own logins with restricted rights.

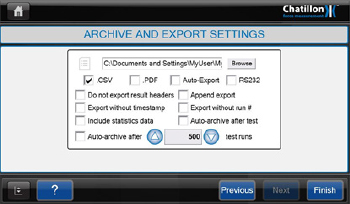

The

CS2-225 integrates seamlessly into your systems. Provided with RS232, the

CS2-225 force tester offers automatic export to external LIMS without human interaction. PDF reports can be printed directly from the machine by connecting a direct or network printer.

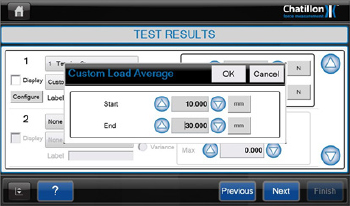

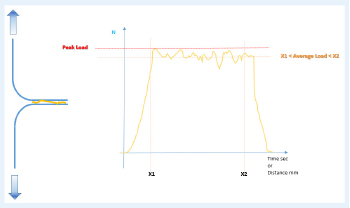

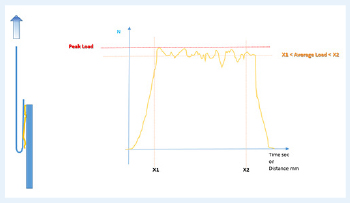

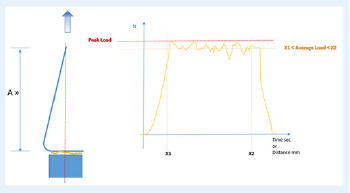

Maximum load, average between two limits and a wide range of additional test set ups relevant to peel testing are easily set with only a few buttons to push.

Vice Grips

Vice Grips

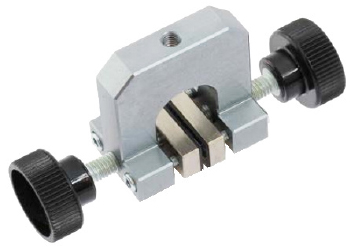

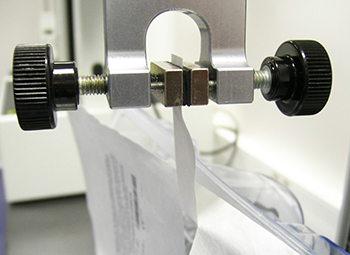

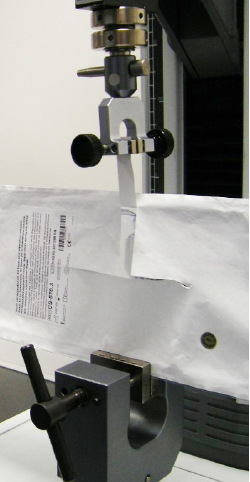

When performing peel tests a

wide selection of grips is available. To obtain the most accurate test results, best ergonomics and most effective test performance while still focusing on a cost-effective solution, we recommend choosing a set of grips that match your specific sample needs while keeping in mind that you might want to use the grips for testing other types of samples as well.

In this example we have used a small

vice grip at the top and a larger vice grip at the bottom. The top grip must be lightweight, easy to use and able to keep a load close to 50N at a maximum.

As the bottom grip is fixed on the machine eye end, we recommend using a larger grip that can also be used for testing a multitude of other applications. By doing so you will get a grip with multiple usage options.

We recommend that you

contact your Ametek Sales Representative if you have any questions when selecting the proper grips for your application.

Load Cell

Load cells are available in different capacities but not all capacities are suited for

peel testing. In this example we used the

CLC020 load cell with a capacity of 100N.

As the level of measurement for the peel test is between 5 and 20N, both a 50 and 100N load cell could be used for the test.

Both load cells will provide the same accuracy and repeatability, but by choosing the 100N load cell the risk of overload in case of user mistakes will be limited.

Description of Test Results

180° T-Peel Test Result

180° Peel Test Result

180° Peel Test Result

90° Peel Test Result

90° Peel Test Result

The length of the strip (A) reduce the angulus change to be close to 90°.

Download this application note as PDF

Download this application note as PDF