Tata Steel manufactures, processes and distributes high-quality steel for products that facilitate life. From Ferro-alloys, tubes, wires and bearings to home appliances, healthcare and mobility aids, Tata Steel is a company driven by innovation that is focused on delivering customized solutions.

The company is the fifth largest steel group in the world, and the second largest steel manufacturer in Europe with production in UK and the Netherlands as well as steel processing companies throughout Europe.

Challenge

When Tata Steel measured the tensile strength (strength at break) and the height of each manufactured steel pellet, testing each individual pellet was a time-consuming, manual process performed by the operator.

To save time, and at the same time gain a higher accuracy, Tata Steel wanted to automate the testing process.

They contacted Technex, the Dutch distributor of Lloyd Instruments materials testers and Chatillon force testing equipment to find a sustainable solution.

Solution

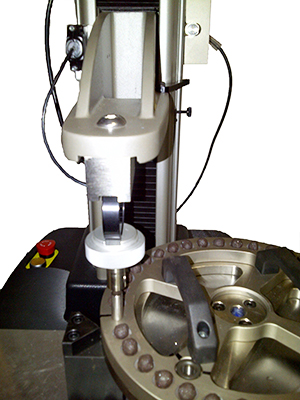

For achieving the correct structure of the steel manufactured, samples made from composites of iron ore pellets were tested. The goal was to automatically measure height and force break.

For this, the

LS1 materials tester from Lloyd Instruments was used in combination with a

100N YLC load cell, a splinter shield with inlock, the

NEXYGENPlus software with a special script and RS232 controllers.

A swivel table with a mold that can carry 30 pellets was designed and manufactured by Technex. It was placed on the base plate of the

LS1. This plate was rotated by a compressed air cylinder that was automatically positioned under the force sensor.

When starting the test program, the force sensor went down and first measured the height of the pellet. If this was the correct size, force was again applied to the pellet to show a break. The break force was detected by the tensile tester and after detection the force sensor went up again.

The table rotated and could then run a new pellet sample so that a new measurement could be made.

One of the strengths of this solution was the

LS1 materials tester working together with the control of the turntable. Technex achieved this through a UCT (User Configurable Test) script and RS232 controllers. The process was repeated in 26 steps and the data was then exported to the factory database.

The pellets were taken from the firing process which means that they still contained moisture. This allowed the break part of the test to be achieved. The complete test was carried out within 60 minutes.

Benefits

Benefits

Prior to the full automation of the test each pellet was measured and tested separately. With the solution provided by the

LS1 materials tester, the pellets were added to the turntable and the test was started. This helped the operator utilize his time better. After 17 minutes the test was complete, and all results were exported via .CSV to Tata Steel’s network for further investigation and analysis.