Essity is one of the worlds’ largest manufacturers and suppliers of health care and hygiene products with sales in more than 180 countries. They have production sites throughout the world and manufacture leading global brands within consumer tissue, incontinence products, baby care and feminine care.

Essity have been using materials testing machines from Lloyd Instruments for decades with many machines located at production sites throughout Europe. These test machines are primarily used for quality control testing of wet and dry tissue paper such as toilet paper tissue and table napkins. Some of the Essity facilities carry out similar tests on other tissue related products.

Challenge

Essity wanted to improve the results of the products being tested, and to make sure that all of their production sites were using the same solution ensuring that they received comparable test results from all of their facilities. This way clarity and consistency could be achieved across the board.

Essity work in accordance to the international standard ISO-12625-5 “Determination of tensile strength, stretch at break and tensile energy absorption”, and it was essential to them that the new machines were able to deliver accurate test results that were compliant to this specific standard.

Solution

To make sure that testing was performed in accordance to ISO -12625-5,

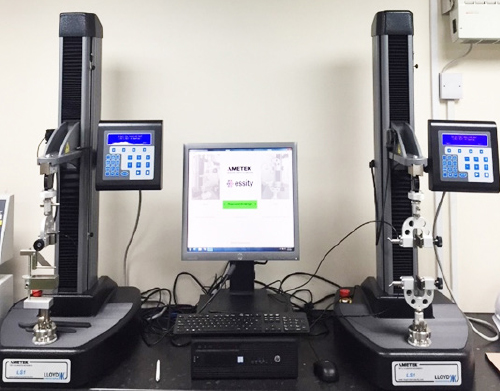

LS1 testing machines from Lloyd Instruments were implemented on the vast majority of production facilities and QA departments throughout Europe. For correct testing, the LS1 machines were supplied with the Finch Grip ideal for wet tissue paper testing and Pneumatic Vice grips for the dry tissue paper testing.

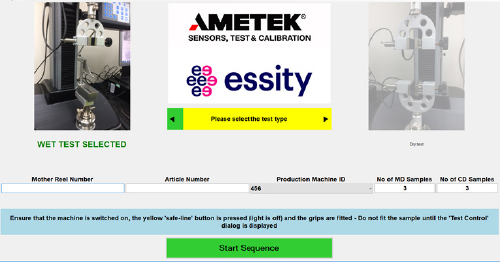

A front-end solution for the

NEXYGENPlus analysis software was also supplied by AMETEK STC. This customized front-end solution simplified the test procedure for the operator and saved the users valuable time on each test performed.

The NEXYGEN

Plus analysis software also allowed automatic export of test results so these could be exported directly into Essity’s internal structure for further analysis.

Benefits

Benefits

By supplying each location with the same materials testing solution, Essity was enabled to gather the test results from various locations for 1:1 comparison and consistency within the products that they manufacture was secured.

By developing the customized front-end for the NEXYGEN

Plus software, Essity saved a lot of time in sample preparation and in carrying out the tests on toilet paper tissue and table napkins.

The LS1 testing machines from Lloyd Instruments were installed in 2017 and within the first year, AMETEK STC supplied more than 35 machines for Essity locations in UK, Sweden, Netherlands, Italy and France where ISO 12635-5 is enforced.

The work of installing

LS1 testing machines on additional Essity locations across the world will continue in 2019.

Download this case story as PDF