By: Joel Schoubert, Product Manager for Chatillon Force Testing Instruments

Force testing is a fundamental part of material analysis and is employed to varying degrees in any field where the mechanical properties of a material, component or prototype need to be characterized. One of the most common applications of force testing is determining the static load force that causes a component or material to fracture or fail. This plays a critical role in the development of mechanical components. For example, exhaustive force testing of vehicle chassis in F1 racing is responsible for drastic improvements in the safety of the sport.

To say that the requirements of force testing vary greatly would be an understatement. For starters, the size of the force applied can range from nanonewtons to meganewtons – around 15 orders of magnitude. Application of compressive, tensile, flexure, fracture and shear forces can require completely different equipment and methodologies. In addition, “static” force testing where test samples are subjected to a slowly varied load force differs fundamentally from “dynamic” force testing where load forces are varied rapidly to gauge the dynamic response of materials at different frequencies.

However, whatever the modality, force range, and application, one factor alone limits the accuracy of any force testing: the grips and fixtures. Variations and inaccuracies in force test measurements can be minimized by ensuring the proper grips and fixtures are being used. Testing at extreme dynamic load frequencies require specialized solutions. A number of "universal" solutions, which meet the requirements of the majority of force testing, already exist.

Choosing the Correct Grips and Fixtures

Choosing the correct mounting hardware for a given force test has many variables which need to be taken in consideration.

Fixtures must be chosen to ensure that the specimen is properly aligned, is rated to the correct force range, provides flexibility and interchangeability, and, of course, under no circumstances allows the test sample to slip. Regardless of the force tester used, selecting the wrong grips and fixtures will result in inaccurate results.

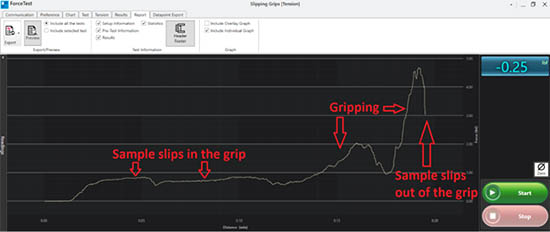

The graphs below shows the results from a tensile force test where slippage occurs due to improper selection of grips:

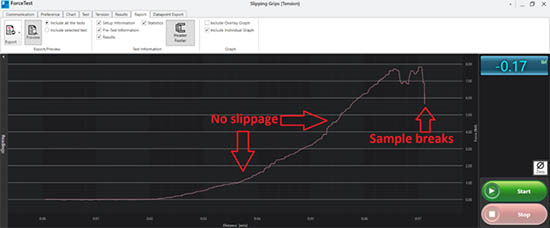

The correct grip faces were used to obtain the next graph. This ensured that no slippage occurred during the test, and that the test results had minimal error.

Grip Types for Tensile Strength Testing

Let's take a look at the most common grip types used in static tensile force testing. Also known as tensile strength testing, this method is used to determine the maximum pulling force that can be applied to a test object before it fails or fractures. For this reason, a firm grip is obviously essential.

Wedge Action Grips are the most commonly used type of self-tightening grip. Self-tightening grips offer the advantage to continuously close tighter as force increase, to and minimize slippage of the specimen during a tensile test.

Wedge grips achieve this by virtue of the fact that the two wedges are pulled together as tensile force is applied to the sample. This is especially advantageous during testing of materials that can elongate under tensile load, causing their diameter to decrease. Initial force can be applied by various methods such as side lever, capstan action wheel or screw.

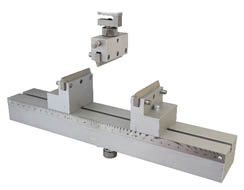

Image: Wedge grips

Vice Grips

Image: Wedge grips

Vice Grips are a type of manually-tightened grip which are ideal for flat specimens including plastic film, paper, sheet metal, fabrics and composites.

Vice grips have a simple design, tightened via thumb screw or T-bar, offering cost advantages over more complicated grip types.

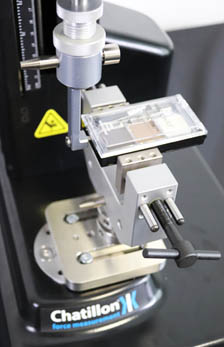

Image: Peel test using Vice grips

Image: Peel test using Vice grips

Image: Tensile test using Vice grips

Image: Tensile test using Vice grips

Eccentric/ Self-tightening Roller grips are another self-tightening grip, which are also well-suited to tensile testing of flat samples. Initial tightening is often performed by lever, and the serrated roller on the

grips prevent slippage which is especially prevalent with malleable samples.

Image: Eccentric Roller grip

Image: Eccentric Roller grip

Image: Self-tightening Roller grip and Terminal Testing fixture

Changing the jaw face pattern or grip surface is an easy way to further safeguard against slippage. Faces are interchangeable for different specimen material and dimensions. Serrated faces are well-suited for plastics, composite material, and metals. Serrated V-shaped jaws are ideal for testing wire and tubing. Softer materials such as films, thin sheets, bands, and paper require smooth or rubber-coated surfaces to minimize slippage.

Different Types of Fixtures for Compressive Force Testing

In force testing, a fixture holds or supports a specimen, as opposed to gripping it. Subsequently, they’re primarily used for compressive force testing. T-slot tables or multithreaded bases may be added onto a force tester to mount custom applications and assemblies.

Bend and Flexing fixtures are used, as the name suggests, for bending materials such as plastic, fiber, and metals at specific lengths.

Bend and flexing fixtures use adjustable anvils or rollers with linear scaling to accurately apply force to the sample in specific locations.

Image: Flexural grip with anvil

Image: Flexural grip with roller

T-Slot and Multithreaded fixtures provide additional fixing when specimens need to be tested as an ensemble. This gives the flexibility in the location and size of the specimen, even if the applied force is offset. Combining the grip with a multithreaded base plate allows mounting flexibility while maintaining the stability of the specimen during testing.

Image: Custom syringe holder based on a T-slot table

Image: Custom syringe holder based on a T-slot table Image: T-slot table

Image: T-slot table

Image: Multithreaded base plate on force tester

Image: Multithreaded base plate on force tester

Image: Multithreaded base plate on force tester

Image: Multithreaded base plate on force tester

Conclusion:

Force testing with the correct grip and fixtures may often seem to require expensive specialized equipment. Repeatability and accuracy of force measurement is limited by the reality and quality of the grips and fixtures used. Selecting the correct grips or fixtures for the given application is essential to maintain accurate, repeatable results.

Making the right decision is crucial for selecting the correct grips or fixtures for the materials being tested. It is important to understand the impact of selecting the incorrect grips or fixtures may have an effect on the test results. These variables can be minimized and controlled based on multiple factors such as; grip faces, load alignment, and type of grip or fixture being used. Making the right choice between a grip or a fixture should be based on the requirements of the material being tested, the specimen size, budget and the space needed for the assembly needed to be tested.